冷轧培训资料

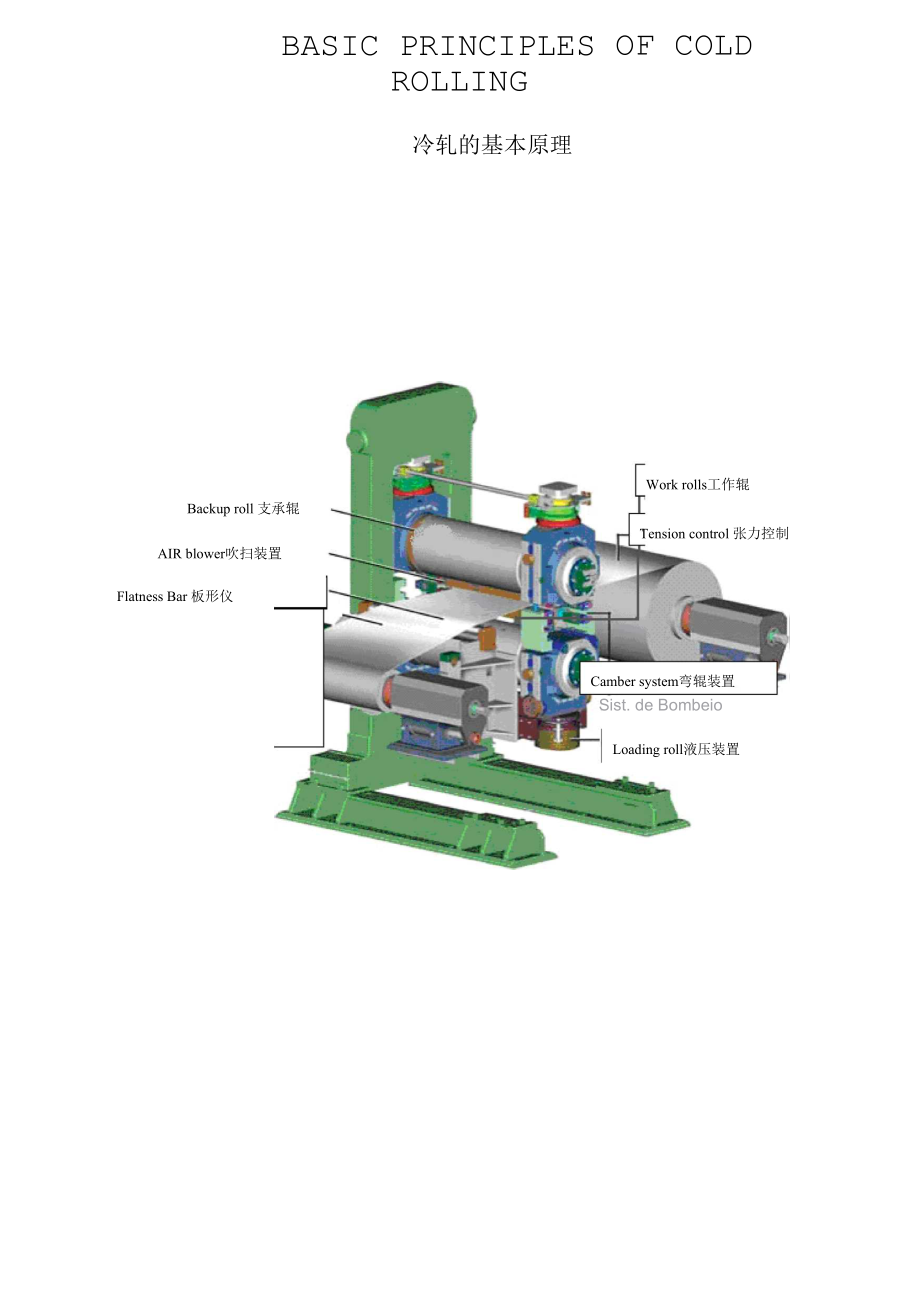

BASIC PRINCIPLESROLLINGOF COLDBackup roll 支承辊AIR blower吹扫装置Flatness Bar 板形仪冷轧的基本原理Work rolls工作辊Tension control 张力控制Camber system弯辊装置Sist. de BombeioLoading roll液压装置Rolling 一 The process of shaping metal by passing it between rolls rotating at the same peripheral speed and in opposite directions to reduce the gauge of a specific product in order to meet a c ustomer's technical specifications.轧制一为了满足客户技术要求,将金属通过两个转动的轧辊 使其厚度减薄,两个轧辊的转动速度一致但是方向相反During the thickness reduction, the metal and work rolls heat up what leads to deformations affecting the metal flatness. Modern rolling mills are equipped with systems that are able to reduce possible flatness problems generated during the rolling process.在厚度减少的过程中,金属和工作辊温度的升高影响板形。

现代轧机安 装了可减少在轧制过程可能出现的板形问题的系统To better understand how the control system works, let's divide this process into parts which can in any way contribute to GOOD or BAD flatness, depending on how it is used.为了更好地理解板形控制系统的运作情况,我们把这一工艺分成几个具体 的部分,任何部分都可能促成良好板形或导致不良板形的产生,关键取决于其 使用状况METAL金属FLATNESS BAR 板形仪TILTING 倾斜CAMBER or BENDING 弯辊SPRAY (COOLANT NOZZLES)喷射(轧制油喷嘴)ENTRY TENSION 入 口张力EXIT TENSION 出 口张力**********1. METAL 一 The metal must have some characteristics as described below:金属一金属必须具备以下几方面的特点Cross Profile (Parabolic shape and symmetrical)横向板形(对称的抛物线)Uniform hardness throughout the coil整卷一致的硬度A defined thickness确定的厚度Known chemical composition名义化学成分Surface free of imperfections (scratches, holes, discoloration) 表面无瑕疵(擦划伤,孔洞和色差)The above characteristics provide for a rolling process free of problems caused by the raw material used.具有上述特点的金属能够排除由原料引起的轧制工艺问题。

To establish common characteristics for our coils, the specification would thus be:为确立卷材的共同特点,规格应该如下:IDEAL CROSS PROFILE理想的横向板形MAX 1,0% 最大值:1.0%MIN 0,0% 最小值:0.0%AATARGET 0,6% 目标值 0.6%EXAMPLE: (B-Average A) X 100/Average A例如:(B-A的平均值)x 100/ A的平均值LONGITUDINAL PROFILE ECCENTRICITY板形纵向偏差SMALLER THAN 1,2%小于1.2%NOTE: The difference between two or more readings on one side in the longitudinal direction within a same revolution (perimeter) of the rolls cannot be more than 1.2%.备注:在轧制的一个周长范围内单边纵向两点或者多点的测量 值偏差不能大于1.2%DIFFERENCE BETWEEN EDGES边部两点差值SMALLER THAN 0,4%小于0.4%(A 主 B) < 0.4%2013-3-30Of those shapes shown above, the one with best technical conditions for good flatness is the symmetrical positive.上述所有板形中,对称的正凸度板形具有最好的板形工艺条件。

FLATNESS BAR (vidimon):板形仪This equipment mounted at mill exit works by replacing man'manual labor to control strip flatness. It is composed of a nucleus (core) with a series of rotors (segments) of various widths, 108,0 mm at the center and the remainder at 54,0 mm, floating over an air cushion located between the nucleus and the rotors. Moreover, each rotor has two pressure transducers mounted in a vertical position in the opposite direction of the nucleus core whose job is to measure the force differences acting over the rotors. See drawing below:板形仪取代了人工操作,安装在轧机出口处以控制带材的板形。

这个装置的组成部分是一个核芯,核芯的外面是一系列不同宽度的转 子(位于中间的转子的宽度为108.0mm,其余的为54.0mm)构成,核 芯和转子的中间是压缩空气此外,每个转子上有两个压力传感器, 它们安装在与核心方向相反的垂直方向上压力传感器用于测量作用 在转子上的压力变化图示如下:Vidimon roll维地蒙板形辊ProcessorAir injection for rotor floating 喷射空气使转子浮动To Transducer到传感器FLATNESS BAR POSITION AT THE ROLLING MILL 板形仪在轧机中的位置The information sensed by the system (more or less pressure) goes to a box that contains the transducers which, in turn, send the data (electrical signal) to a central computer (the host) where the data is then processed.由这个系统(大小不等的压力)感应的信息传到信号感应器箱, 感应箱中的传感器把数据(电信号)传到处理数据的中央计算机。

Any deviations sensed by the vidimon will be treated separately by the control computer (the host) which will take the necessary measures according to the existing logic in the control system.任何由板形辊检测到的偏差将由主机根据控制系统的处理逻辑采 取必要的措施进行分开处理Below, we can see how the signs are made available to the operation desk. This allows the operator to intervene, if necessary.下图显示了信号在操作台是如何有效工作的如有需要操作手可 以对其进行调节Process to control flatness板形控制过程Tilting :倾斜ing rollA module to correct the difference in tension sensed by the flatness roll between one side and the other in the sheet/foil in order to obtain linear efforts on both sides of the strip. In order to perform this activity, the system orders an increase or reduc tion in pressure to the mill'r solload force) aiming for symmetry.为了使带材两边获得线性板形,我们用一种方法来修正板形辊检 测到的带材两边之间的张力差。

为了实现这项功能,系统给轧机下达 一个增加或减小轧制压力的指令以实现带材板形的对称CAMBER or BENDING 弯辊Used to correct parabolic errors coming from the metal as well as to copy the type of profile of the incoming reroll, be it positive or negative. This action comes from the hydraulic cylinders mounted on the rolling mill structure which, when requested, imprints a force over the work roll chocks thus changing the work rolls geometry.用来纠正金属的抛物线板形,同时复制来料的板形,无论是正 弯还是负弯当需要时,位于轧机上的液压缸施力于工作辊轴承座 上,从而改变工作辊的形状When POSITIVE CAMBER or BENDING is requested, the work roll geometry is shaped as below:正弯时工作辊的几何形状如下:正弯When NEGATIVE CAMBER or BENDING is requested, the roll geometry is shaped is below:负弯时工作辊的几何形状如下:BASIC PRINCIPLES OF COLDROLLINGProcess for Flatness Control板形控制过程轧制油喷射梁SPRAY:喷淋Upon receiving data from the host computer via the Flatness Bar on how the metal is behaving, the data is then relayed to the spray system in order to eliminate flatness errors caused by heating differences over the sheet/foil width.当主机接收到通过板形仪发来的关于金属运行情况的数据时,这 些数据会被传递到喷淋系统以消除卷材或箔材宽度方向上由于热量差 导致的板形缺陷。

mnOil distribution 轧 制油的分布Spray control depends on the data received by the Flatness Bar. Its main goal is to keep the rolls in thermal balance in order to eliminate flatness deviations as well as to sustain the flatness parameters throughout the rolling process.喷淋控制系统取决于板形仪收到的数据其目的在于保持轧辊的 热平衡以消除板形缺陷,同时保持板形参数在整个轧制过程中的一致 性Each rolling mill has its own characteristic configuration and, in this case, we are using an intermediate mill as reference whose system is thus distributed: 27 zones (with five spray nozzles per zone) and 10 different oil levels.由于每台轧机都有自己的配置特点,因此我们用具有27个区(每 个区中有5个喷嘴)和10个不同的油位的中轧机作为参考。

ENTRY TENSION:入口张力:A fundamentally important element in flatness since depending on its use there may be high instability in mill entry causing metal speed variations in the roll bite.入口张力控制是板形影响因素中一个至关重要的因素,不同的张 力使用可能导致轧机入口处的高度不稳定性,从而导致金属速度在轧 制单元(咬入)的不稳定性The back tension in sheet rolling mills must be kept constant throughout the rolling process to prevent losses in flatness performance and gauge.轧机在轧制带材的整个过程中必须保持后张力的稳定性以避免板 形和厚度偏差In the foil rolling process, the back tension influence on flatness is not so much since we used tension to control metal thickness.后张力对轧制箔材的板形影响不及对轧制带材的影响,因为轧制 箔材时,后张力主要用来控制厚度。

EXIT TENSION:出口张力:This is a fundamentally important element to maintain flatness outside the machine; if used inadequately, we will have coil cross profile errors which become worse during coil winding.这是维持产品轧后板形的一个重要因素如果出口张力不够,将 出现横向板形问题,这一问题将在卷取时恶化As with entry tension, back tension must be kept constant until the coil is fully wound, including foil rolling, so that at the end of the winding there will not be any flatness errors which could have been introduced by increased tension for lack of uniformity.对于入口张力,后张力必须保持一致直到卷取完毕(包括箔 轧),只有这样,在卷取的最后阶段才不会有任何由于不均衡性而增 加张力所导致的板形问题。

An aluminum foil rolling mill aims for good gauge, surface quality that will meet Customers Specifications as well as good mechanical properties for the downstream processes, i.e., meet all requirements at low cost.箔轧机的目的在于生产厚度和表面质量良好的箔材以达到客户的 标准,同时生产机械性能良好的产品以满足后续生产的要求,也就是 以低的成本满足所有要求THE BASICS OF THE COLD ROLLING PROCESS冷轧工艺的基础Metal is deformed (cold hardened) and reduced to a specific gauge under pressure induced by a pair of rolls through which passes the metal.金属在通过一对轧辊时,承受轧辊对金属所施加的压力,从而产 生变形(冷加工硬化)并且减少到某一特定的厚度。

HARDENING力口工硬化The metal's hardens by plastic deformation.金属通过塑性变形实现硬化To better understand what is cold hardening: A body that is pull or deformed at up a certain limit will return to its point of origin, and this is called elastic deformation; but, if pulling or deformation is increased, the material will not return to its original shape and this is called plastic deformation.以下解释是为了更好地理解冷加工硬化的定义:物体被拉伸到某 一极限值后能够回复到原有状态的叫弹性变形;但是,如果拉力增大 或变形增加,物体不能回复到原有状态的叫塑性变形During hardening, the material's mechanical properties change:加工硬化过程中,金属的机械性能发生了变化:The limit of elasticity is reduced弹性极限值降低The limit of tensile strength increases抗拉强度极限值增加Metal hardness increases金属的硬度增加Elongation decreases延伸率降低In order to be able to work with the metal during rolling, this hardening process reaches a certain stage where it will not be easy to work with it during rolling so the metal must receive heat treatment before continuing the rolling process.为了能够在轧制过程中让金属发生变形,当加工硬化达到一定程 度不容易继续发生变形减薄时,就必须在继续轧制前对金属进行热处 理。

The work pressure will depend on the contact area between the sheet and the work rolls. If this area is small, the load will be low; if the area is large, the load will be higher.轧制压力取决于板材和工作辊之间的接触面积如果接触面积 小,所需要的压力就小;反之,所需的压力就大When the rolls are used in the rolling process, an arch is formed on the work roll extremities called roll camber or bending.当轧辊被用于轧制时,在工作辊的周圈形成一个叫弯辊的弓形形 状Roll camber/bending can be:弯辊的形状如下:POSITIVE正凸度负凸度Roll camber can be produced in two ways: 轧辊凸度可以通过以下两种方式产生:a) Physical roll camber or roll crown: That which is produced during roll grinding, depending on the type of mill and how it will be used.物理凸度:根据轧机的类型和轧辊的用途在磨辊工序形成。

b) Thermal roll camber or roll bending: That which is produced by the thermal expansion of the work rolls during the rolling process. This is different from the physical roll camber, it varies from beginning to end of the coil and it will depend on the work purpose (higher or lower metal reduction).热凸度:形成于轧制过程中工作辊的热膨胀与物理凸度不同, 热弯辊的凸度在轧制卷材的整个过程中是变化的,它取决于轧制的目 的(金属的压下量决定)This occurs due to the difference in speed, work rolls vs. metal speed. The difference in speed is due to volume of entry metal and volume of exiting metal when the gap between rolls is constant. This, in turn, increases the length of the rolled strip.发生在工作辊和轧件速度不一致的情况下。

当工作辊之间的间隙 一致时,两者间速度的差异取决于入口金属和出口金属的体积比这 也导致了轧制带材长度增加A= strip speed smaller than roll speedA=带材速度小于辊速N= strip speed the same as the roll speed (neutral point)N=带材速度等于辊速(中性点)B= Strip speed higher than roll speedB=带材速度大于辊速During rolling, the thermal expansion is different along the work roll work races, i.e., the center tends to be hotter than the roll edges which could cause % and 1/8 pockets which are always related to the rolling effort.车L制过程中,同一棍上的热膨胀是不一致的,比如辊中心的温度 要高于辊边部,根据轧制的不同类型,在辊的% and 1/8处产生鼓包。

DEFINITION OF FLATNESS:板形的定义Flatness is the difference in pressure of the strip against the flatness bar across the strip width. The smaller the pressure difference, the better is the flatness and the higher the difference, the worse flatness will be. Flatness differences can be measured in the strip by cutting longitudinal slices in coil length. When placed over a flat surface, there will be differences in length and these differences are the errors that must have been removed.板形指在宽度方向上,带材给予板形仪的压力差。

差值越小,板 形越好;差值越大,板形越差可通过在卷材的长度方向上取纵切片 来测量板形差这个纵切片与平直表面的长度差就是必须要消除的板 形偏差a= original lengtha=原始长度UNIT I: I" is the measurement unit used to measure flatness.单位I: I"是测量板形的单位Look at the drawing:请看下图:a=1000,0mmUnit I" = (b/a )x105 单位I" = (b/a )x105Example: Cut a section of a= 1000mm in length; by measuring the different segment lengths, it can be seen that the larger difference among the segments was =0, 20mm at the longer length; by applying the formula, we have :例如:切一个长度a= 1000m m的截面,通过测量不同切片的长度 差,可得出这几个切片间长度差的最大值为0.20mm;再套用以下公 式,可得出:UNIT I = (20/1000) x 105 = 20BASIC PRINCIPLES OF COLDROLLINGThus, we can conclude that the error was 20 I" units of flatness. 因此,我们可得出板形偏差值为20 “I"单位。

DURING THE ROLLING PROCESS:在轧制过程中:During rolling, we can have several types of situations which can be seen in a video monitor as below:在轧制过程中,有几种不同的情况,详见以下可视监控图:Symmetrical positive profile对称的正凸度板形The above picture shows a symmetrical positive profile which will be our normal working condition. In this case, the operator will not need to do any intervention since the machine is doing what is desired; it must be only monitored.上图展示了正常工作状态下的对称的正凸度板形在这种情况 下,操作手无需做任何修正,因为设备按照期望在运行,只需监控就 可以了Negative symmetrical profile:对称的负凸度板形This picture shows a negative symmetrical profile which is not a normal work condition since it will concentrate tensions at the edges. The operator must change this work condition in order to achieve the desired work profile. To make the change, the operator must use the flatness screen to change the curve to the correct value stated in the work order. Or, in case it is correct, it must increase the negative value reference until the configuration achieves a normal profile as shown in previous picture.上图展示了一个非正常运作情况下的对称的负凸度板形,这种板 形使张力集中在两边部。

操作手必须改变这种运行状态以生产出符合 期望的板形为了改变这种状态,操作手必须依据板形显示屏改变板 形曲线以调整工作指令参数或者,如果参数是正确的,必须增大负 参考值直到整个配置达到如前一个图片所示的对称的正凸度板形NOTE: Only in special cases we will we have a rolling configuration as shown in the above figure; all these cases will be noted in the work orders.备注:只在一些特殊情况下,我们才会看到如上述数据显示的轧 制配置;这些情况会在工作指令中显示ASYMMETRIC PROFILE对称的板形楔形The picture above shows two wedge-shaped profiles. These are the worst profiles since the material cannot be modified to the point where we would have two symmetrical edges thus forcing the operator to make the mill uneven in order to prevent the flatness problem from becoming worse. To solve this problem, the operator will use the flatness screen to look for symmetry by tilting the mill using the tilting control aiming to reduce waves in one of the edges.上述图表展示了两张楔形板形的图片。

这些是最差的板形,因为 轧件不能被修复成边部对称的板形,因此操作手不得已要倾斜轧机以 防止板形恶化为解决此问题,操作手通过倾斜控制从板形显示屏上 寻找对称点以减少其中一边的边浪NOTE: Whenever the operator must use a value for tilting, this will not be related to a rolling operational failure but to incoming material.备注:操作手无论何时都必须使用一个值来进行倾斜,这种板形 与来料有关,而与轧制过程中的操作失误无关In summing up, we can say that when the strip profile is symmetrical and the operator wishes to increase or reduce its intensity, he will have to reduce or to increase the bending which, in turn, will change the profile. When the profile is in its asymmetrical shape, the operator will have to tilt the mill in order to obtain profile symmetry.总之,我们敢说当带材的板形是对称的时候,而操作手希望增加 或减少其幅度,他就要减少或增加弯辊以改变板形。

如果板形是不对 称的,操作手就要倾斜轧机以实现板形的对称A change in the Bending will change flatness, as shown below. 如下图所示,改变弯辊度将改变板形Top: Center buckle 一 Bottom: Edge wave 上张图:中浪-下张图:边浪EDGE CORRECTION边部调整During the rolling process, certain types of corrections may be necessary due to the equipment's own correcting limits. As shown above, a symmetrical profile can be seen highlighting the edges in relation to the profile as a whole. To solve this type of problem, the operator can make a lateral correction by changing the value in the flatness screen.在轧制过程中,根据设备本身的调整极限,几种类型的调整是必 须的。

正如上图所示,板形对称,但是边部突出为解决此类问题, 操作手可通过改变板形屏上显示的数值来做边部调整During the process of introducing metal into the machine, it is necessary that the metal is already adjusted at roll exit so when by the time it reaches the spool, it will have the best flatness possible; in case strip winding is irregular, the entire coil will be compromised; if that is a final pass, it can be a quality problem and the coil may be scrapped.在把金属穿带的过程中,很有必要在轧辊出口处将金属调整好, 这样金属卷到套筒的时候才可能达到最好的板形万一带材卷取异常 将会影响到整个卷;如果是最后一个道次,可能会导致质量问题,很 有可能整卷都会报废。

In order for the flatness condition be considered the best possible, we must use the concepts seen here.为达到最好的板形条件,我们必须使用这里的概念GAUGE (THICKNESS)厚度THICKNESS GAUGE is made up of an ionizing irradiation source and a receptor; the metal passes through the emitter and the receptor, deviations in relation to a curve residing in the instrument will be shown.测厚仪由一个游离照射源和一个接收器组成;金属在发射器和接 收器之间通过,与仪器里相关曲线的偏差会显示出来WORK MODE is the selection that Process personnel adopts for the automatic correction of thickness deviations. These can be:工作模式是程序控制员选择自动纠正厚度偏差的模式。

包括:GAP: A fixed space to reach the target with variable load. 辊缝:通过不同的轧制力达到设定的固定间隙LOAD: Fixed LOAD with variable space to reach the target. 轧制力:通过具有不同的间隙达到设定的固定轧制力The difference between GAP and LOAD is that during the GAP mode, the system is harder, flattening large peaks, since the correction system through the LOAD modulates (copies) existing errors.辊缝和轧制力的不同之处在于,处于辊缝模式的时候,系统刚度 增强,平行度达到极限值,因为通过轧制力模式的系统修正存在错 误Still related to these two modes, we can associate the correction through UNWINDER TENSION and SPEED.继续讲与这两个模式相关的内容,我们把厚度调整与卷取张力和 速度结合起来。

TENSION: When it is increased, it causes gauge reduction and when it is reduced, the gauge is increased.张力:当增大时,厚度减小;反之,厚度增大SPEED: Works the same as TENSION (higher speed, lower gauge - lower speed, higher gauge).速度:与张力的工作方式一样(厚度随着速度的增加而减小)Thus, during rolling, the thickness gauge reads the deviation and sends data to the AGC equipment which, depending on the size of the error, sends in an order of higher or lesser intensity for correction through one of the systems in use at the moment.因此,在轧制过程中,厚度控制仪读出偏移,并把数据发到自动 厚度控制仪。

自动厚度控制仪根据差值的大小,立即给这个系统发一 个较高或较低的纠错指令Processor程序控制ACTION反馈虻人 SPEED速度LOAD轧制力 TENSION张力ERROR错误(Deviation)偏差2013-3-30。